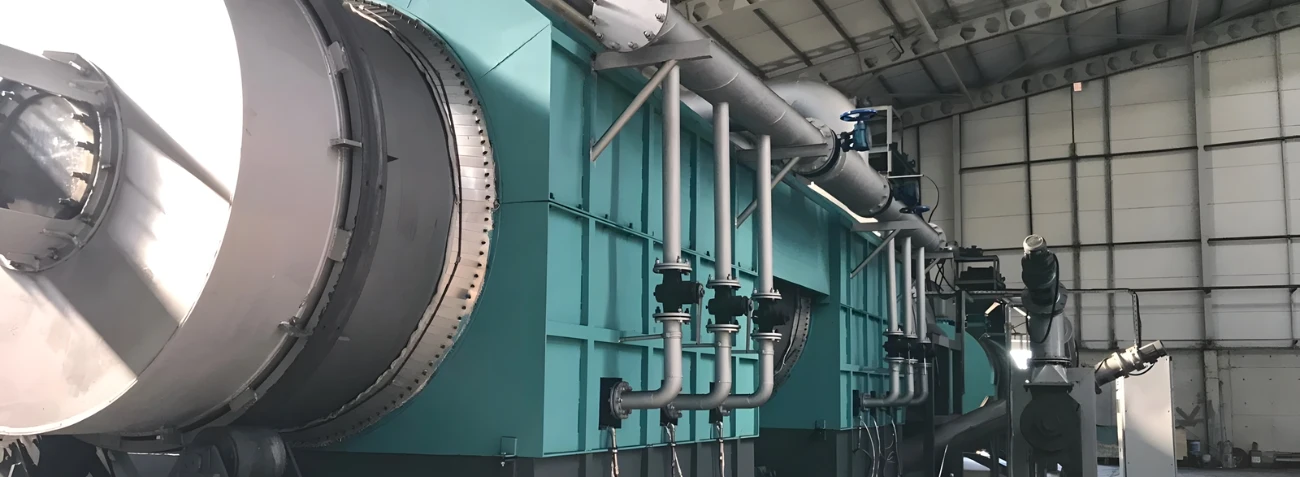

Wood Processsing Waste into Biochar Project in Korea

- Project Time: November 2024

- Recycled Biomass: wood chips

- Machine Capacity: 10-15m³/h

- Biochar Use: carbon sequestration, soil improvement

Biochar production equipment is an industrial facility for recycling waste biomass into biochar under sustainability. Biochar machine of Beston Group realizes large-scale, highly automated, low-emission production, consistency of biochar. What’s important, the carbon content and H/C molar ratio of biochar meet the standards of multiple industries. Therefore, more carbon neutrality advocates have reached strategic cooperation with us to jointly achieve biochar carbon removal goals. With successful biochar production project deliveries worldwide, Beston Group supports global customers in meeting sustainability targets:

Exciting news! Beston BST-50S biochar production equipment is Puro.earth technology vetted. Our R&D in pyrolysis technology has paid off. It means we can offer advanced biochar solutions and an efficient way to earn carbon credits. The equipment creates significant value for investors:

BST-50S technology complies with global carbon removal (CDR) standards. It supports carbon credit trading and carbon neutrality goals.

BST-50S biochar machine can produce high-quality biochar meets European Biochar Certificate (EBC) Standard. Therefore, it brings:

BST-50S complies with EU standards for emissions control. It ensures efficient operation while minimizing pollutants.

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Model BST-50S biochar machine delivers an annual output of 6,000 tons of biochar. It enables long-term sequestration of up to 12,000 tons of CO₂. Perhaps you don’t have a clear idea of such a amount. Following figures illustrate the measurable impact BST-50S biochar pyrolysis equipment creates in both environmental & economic terms:

CDR credits generated

forest carbon sink restored

steel production CO₂ emissions offset

steel production CO₂ emissions offset

carbon credit revenue

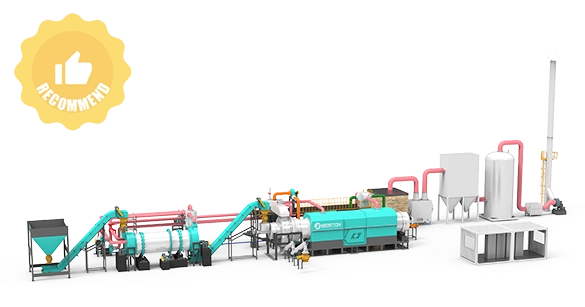

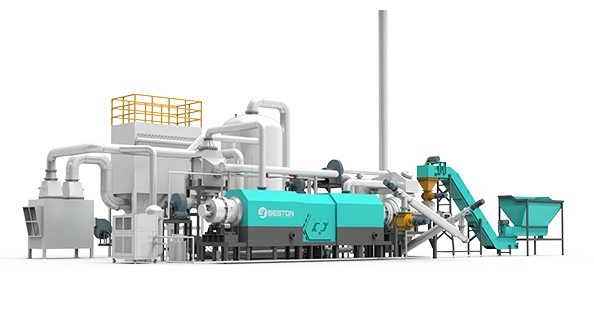

Our lastest BST-50S model meets growing demand for large-scale carbon removal. Here are our key technological breakthroughs for processing capacity:

The biochar production equipment integrates two core designs to ensure safe and stable operation of the equipment for over 7,200 hours annually.

The pyrolysis equipment features a dual-cylinder heating structure enables multi-stage carbonization, with a processing capacity exceeding 10 m³ per hour.

7,200+ hours per year stable operation not only ensures the stability of product quality of biochar making machine, but also helps investors to maximize project ROI.

Starting a Carbon Dioxide Removal (CDR) project through biochar production has become a popular option for recyclers. However, to establish a certified CDR project, a comprehensive understanding of the lifecycle assessment of biochar production is essential. This is the most fundamental basis for third-party certification platforms to evaluate carbon removal projects. Therefore, you can follow the steps below to evaluate your biochar production equipment:

For CDR project certification, the source of biomass must prove its sustainability. In particular, for forest biomass, relevant sustainable forest management certification is required, such as FSC, SFI or PEFC certification. In addition, greenhouse gas emission data including the process of biomass cultivation, acquisition and transportation must be recorded in detail and submitted to the certification platform for evaluation.

Unlike charcoal making machine, in biochar production, producers need to record detailed data and submit it to a third-party certification platform. This ensures compliance with the requirements of the CDR project certification. Specific requirements include:

The use of biochar in the use phase determines its carbon sequestration efficiency and environmental benefits. Suitable application areas include agricultural soil improvement, forestry carbon sinks, land restoration, building materials and livestock feed. These uses can enhance soil quality, reduce greenhouse gas emissions and promote sustainable development.

Understanding what is biochar made of is essential for biochar machine. Biochar is derived from a wide range of biomass materials, each contributing unique properties to the end product. Below is a list of commonly used raw materials:

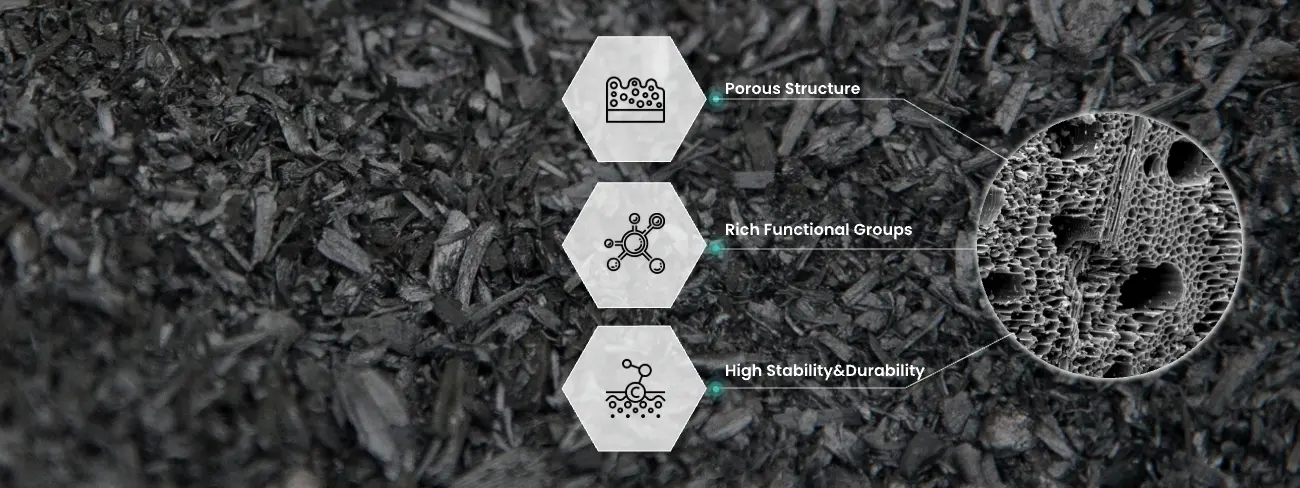

Biochar is a carbon-containing substance formed by pyrolysis of biomass (such as wood, agricultural waste and other plant residues). Biochar production equipment ensures pyrolysis reaction takes place under high temperature and oxygen-free conditions. Such a production method gives biochar the following characteristics:

Biochar has abundant micropores on its surface and inside. The pore structure gives biochar a high specific surface area, which can reach between 200-500m2/g. This structure enables biochar to have efficient adsorption capacity and helps to store water and nutrients.

The surface of biochar usually carries a variety of functional groups (such as hydroxyl, carboxyl, etc.). These groups provide many active sites to form chemical bonds with minerals, microorganisms, organic matter, etc., thereby improving its adsorption capacity.

The carbon in biochar exists mainly in aromatized and structured forms. Therefore, it has strong chemical and thermal stability and degrades very slowly in the soil or environment. Generally, biochar can even exist in the soil for hundreds of years.

Before entering biochar production equipment, the biomass must meet certain feeding requirements. Its moisture content should be less than 15%, and the particle size should be uniform small pieces less than 20mm. In addition, we recommend customers to use raw materials with good fluidity and low dust content. The pretreatment facilities we can provide include: dryer, crusher and drum screen.

When the reaction temperature stabilizes, the organic volatiles in the biomass are precipitated to form combustible gas. Its components include hydrogen, methane, ethane, carbon monoxide, etc. The combustible gas re-enters the combustion system through a pipeline. Subsequently, it replaces the external fuel to continue to provide energy for the biochar plant.

The high-temperature biochar in the main furnace is discharged through a water-cooled screw conveyor. The cooling water in the conveyor exchanges heat with the biochar. Three such conveyors can reduce the temperature of the biochar to below 45 degrees Celsius. The cooled biochar enters a dedicated facility for storage.

With the global attention paid to climate change issues, carbon dioxide removal market has developed rapidly. The global biochar carbon credit market size is US$680 million in 2023 and is expected to exceed US$2 billion by 2032. In addition, biochar has become an important participant in the carbon credit trading market. In recent years, it has contributed more than 90% of all carbon credits. Thus, it drives the growth of demand for biochar machine.

With the advancement of the circular economy, biochar is increasingly used in agriculture, construction, forestry and other environmental fields. Biochar forms a diversified application model. These applications covering multiple fields not only benefits biochar users, but also promote the increasing market demand for biochar production equipment. The environmental protection characteristics of biochar make it a key material in sustainable development strategies.

Traditional biochar production methods can no longer meet the current market requirements for biochar quality. For example, quality standards such as H/C molar ratio, PAHs (polycyclic aromatic hydrocarbons), and heavy metal content have become important indicators. At present, the mainstream trend has shifted to large-scale and continuous production. Biochar equipment not only improves efficiency, but also ensures higher quality biochar products.

The two-way policy push has made the machine market prospects more promising.